Electric Vehicle Supply Chain and Logistics

Electric Vehicle Supply Chain and Logistics: Navigating the Road to Sustainability. The global shift towards electric vehicles (EVs) has been nothing short of transformative, heralding a new era of sustainable transportation. As EV adoption accelerates, the spotlight has increasingly turned to the supply chain and logistics that underpin this burgeoning industry. From sourcing raw materials to delivering finished vehicles, the EV supply chain is a complex and dynamic ecosystem that plays a critical role in shaping the future of mobility.

Electric vehicles (EVs) are estimated to represent over 60% of new global car sales by 2030. Many countries have also announced that they will ban the sales of traditional internal combustion engine (ICE) vehicles in the next decade. As the transportation of ICE vehicles and their parts has always been a significant part of global shipping, companies shipping or relying on ICE products must adjust their supply chains to accommodate this new development in the automotive industry.

The Backbone of EVs: Raw Material Sourcing

At the heart of every EV lies its battery, typically a lithium-ion variant, which accounts for a significant portion of the vehicle’s cost and weight. The production of these batteries hinges on the availability of key raw materials such as lithium, cobalt, nickel, and graphite.

However, sourcing these materials poses several challenges:

- Geopolitical Risks: Many of these resources are concentrated in regions with unstable political climates, such as cobalt in the Democratic Republic of Congo.

- Environmental Concerns: Mining and refining processes can have significant environmental impacts, prompting calls for more sustainable practices.

- Ethical Issues: Ensuring responsible sourcing and eliminating child labour from the supply chain are critical priorities for manufacturers.

To address these challenges, companies are exploring alternative materials, enhancing recycling programmes, and investing in ethical sourcing initiatives.

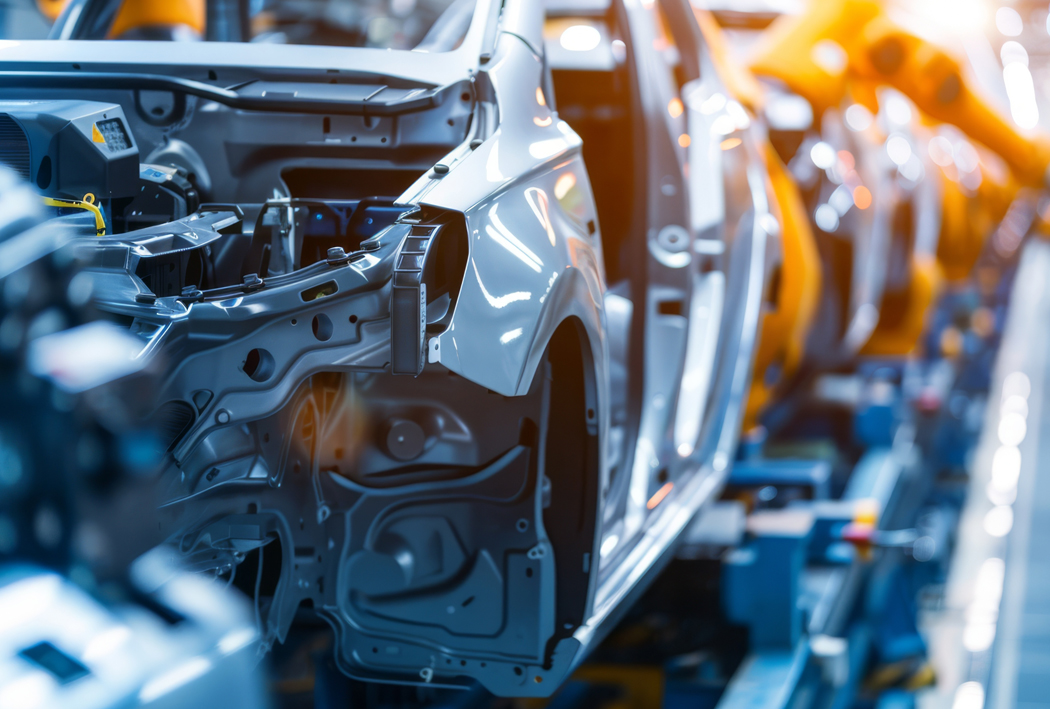

Manufacturing and Assembly

The transition to EVs has upended traditional automotive manufacturing. Unlike internal combustion engine vehicles, EVs require fewer components and involve a more streamlined assembly process. This has led to:

- Vertical Integration: Companies like Tesla are increasingly adopting vertical integration strategies to control more of the supply chain, from battery production to software development.

- Gigafactories: The rise of massive battery manufacturing plants, or gigafactories, has become a hallmark of the EV industry. These facilities aim to meet growing demand while achieving economies of scale.

- Technological Innovations: Advances in automation, AI, and robotics are revolutionising manufacturing, enabling faster and more efficient production.

Distribution and Logistics Challenges

The logistics of distributing EVs and their components present unique hurdles:

- Battery Transportation: Lithium-ion batteries are classified as hazardous materials, requiring specialised handling, packaging, and compliance with strict regulations.

- Global Supply Chain Disruptions: The COVID-19 pandemic and geopolitical tensions have highlighted vulnerabilities in global supply chains, emphasising the need for resilience and diversification.

- Last-Mile Delivery: As EV adoption grows, ensuring timely and efficient delivery to dealerships and consumers becomes increasingly important.

Circular Economy and Recycling

A sustainable EV supply chain doesn’t end with the sale of a vehicle. End-of-life management is a crucial component, particularly for batteries. Recycling initiatives are gaining momentum to:

- Recover valuable materials like lithium, cobalt, and nickel.

- Reduce dependence on virgin raw materials.

- Minimise environmental impacts.

Companies are investing in second-life applications for EV batteries, such as energy storage systems, to extend their usability and reduce waste.

Future Trends in EV Supply Chain and Logistics

As the EV industry matures, several trends are poised to shape its supply chain:

- Localisation: To mitigate risks and reduce carbon footprints, manufacturers are increasingly localising production and sourcing.

- Blockchain Technology: Ensuring transparency and traceability in the supply chain through blockchain can help address ethical and environmental concerns.

- Green Logistics: Leveraging renewable energy and sustainable practices in logistics will be key to reducing the overall carbon footprint of the EV ecosystem.

- Collaboration: Partnerships between automakers, tech companies, and governments will be essential to overcome supply chain bottlenecks and accelerate innovation.

Conclusion

The supply chain and logistics behind electric vehicles are as transformative as the vehicles themselves. By addressing challenges and embracing innovative solutions, the EV industry can build a resilient and sustainable foundation for the future of mobility. As stakeholders across the value chain work together, the promise of a greener, cleaner transportation system becomes increasingly attainable.

About this Blog

If you have any questions about this blog or the current timelines for shipping or Freight Forwarding, please contact us via our website at www.uneek-group.com

Address: Uneek House, Amberley Way, Hounslow, Middlesex, TW4 6BH

Call: +44 (0) 20 8569 4949

E-mail: [email protected]

Website: www.uneek-group.com

Blog Title: Electric Vehicle Supply Chain and Logistics

Blog Author: Mark Watts